|

Here

are two

examples of combined construction (prefabricated modular + on

site):

1)

Condos du Manoir Fortin (Mont-Tremblant /

St-Jovite)

Click

here to see a video presentation about the project

Click here to see a video presentation about prefabricated

modular construction

Modules manufacturer:

(Main contractor)

Les Industries Bonneville

Prefabricated modular constructions.

Person in charge: Mr. Gaétan Filteau

Site internet:

www.maisonsbonneville.com

E-mail:

info@bonneville.qc.ca

Addresses:

Beloeil

601, Rue de l'Industrie

Beloeil (Québec)

J3G 4S5 - Canada

Phone: (450) 464-1001

(514) 990-1624

Québec

2470, Hamel West Blvd.

Québec (Québec)

G1P 2J1 - Canada

Phone: (418) 687-4621

Hull

2 Pont Alonzo Wright Road

Chelsey (Québec)

J0X 1N0 - Canada

Phone: (819) 771-6960

Arnprior

82 Calebogie.

Arnprior, (Ontario)

K1S 3G8 - Canada

Phone: (613) 622-0399

Contractor:

Vision Nordique

Person in charge: Mr. Gilles

Fortin

719 rue Messier

Mont-Tremblant, (Québec)

J8E 3B9

Canada

Phone: (819) 425-4744

Fax: (819) 425-5307

Developer:

Gestion Marcel Fortin & Fils

Investor in the seniors housing

field.

Person in charge: Mr. Marc-André

Fortin

Site internet:

www.manoirfortin.com

E-mail:

marc-andre@manoirfortin.com

Address:

719 rue Messier

Mont-Tremblant, (Québec)

J8E 3B9

Canada

Phone: (819) 681-0618

Fax: (819) 425-5307

Architect:

Michel Tellier architect

Person in charge: Mr. Michel

Tellier

Site internet:

www.tellier-architecte.com

E-mail:

michel@tellier-architecte.com

Joliette office:

629, rue de la Visitation, Saint-Charles-Borromée,

(Qc) Canada J6E 4P8

Phone: 1 (450) 759-3093

Fax: 1 (450) 759-0323

Engineers:

Genivar

Person in charge: Mr. André Lafleur

Site internet:

www.genivar.com

E-mail:

alafleur@genivar.com

Address:

5858 Côte des neiges, 4ième étage

Montreal, (Québec)

H3S 1Z1

Canada

Phone: 1 (514) 340-0046

Fax: 1 (514) 340-1337

Town planners:

Arbour & associés

Person in charge: Mr. Pierre Côté

E-mail:

cpierre@arbour.ca

Phone: 1 (819) 326-8190

Fax: 1 (819) 326-8730

Surveyor:

Murray Patenaude Maltais

Person in charge: Mr. Dany Maltais

E-mail:

d.maltais@mpmag.com

Address:

517 Charbonneau, bureau 100

Mont-Tremblant, (Québec)

J8E 3H4

Canada

Phone: 1 (819) 425-9808

Fax: 1 (819) 425-8014

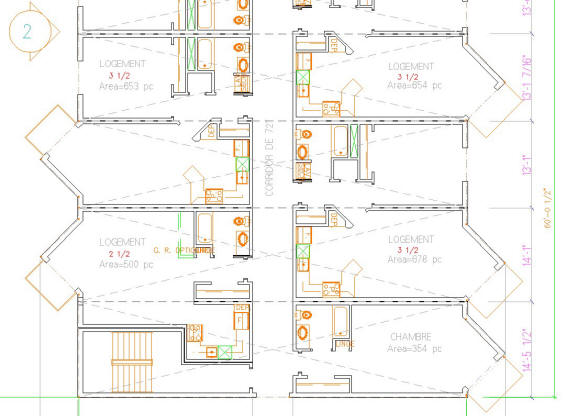

2)

St-Amour seniors housing - Study (Acton Vale)

Modules manufacturer:

(Main contractor)

Les Industries Bonneville

Prefabricated modular constructions.

Person in charge: Mr. Gaétan Filteau

Site internet:

www.maisonsbonneville.com

E-mail:

info@bonneville.qc.ca

Addresses:

Beloeil

601, Rue de l'Industrie

Beloeil (Québec)

J3G 4S5 - Canada

Phone: (450) 464-1001

(514) 990-1624

Québec

2470, Hamel West Blvd.

Québec (Québec)

G1P 2J1 - Canada

Phone: (418) 687-4621

Hull

2 Pont Alonzo Wright Road

Chelsey (Québec)

J0X 1N0 - Canada

Phone: (819) 771-6960

Arnprior

82 Calebogie.

Arnprior, (Ontario)

K1S 3G8 - Canada

Phone: (613) 622-0399

Architect:

Michel Tellier architect

Person in charge: Mr. Michel

Tellier

Site internet:

www.tellier-architecte.com

E-mail:

michel@tellier-architecte.com

Joliette office:

629, rue de la Visitation, Saint-Charles-Borromée,

(Qc) Canada J6E 4P8

Phone: 1 (450) 759-3093

Fax: 1 (450) 759-0323

|